Jamco America is a commercial aircraft interiors company based in Everett, Washington that designs and manufactures products such as premium seating, and many other cabin furnishings for commercial aerospace clients like Airbus and Boeing. The company also works directly with airlines doing modifications to retrofit their existing aircrafts. Jamco America is the largest subsidiary of Tokyo-based Jamco and is made up of several small product development teams, with engineers who specialize in different product lines.

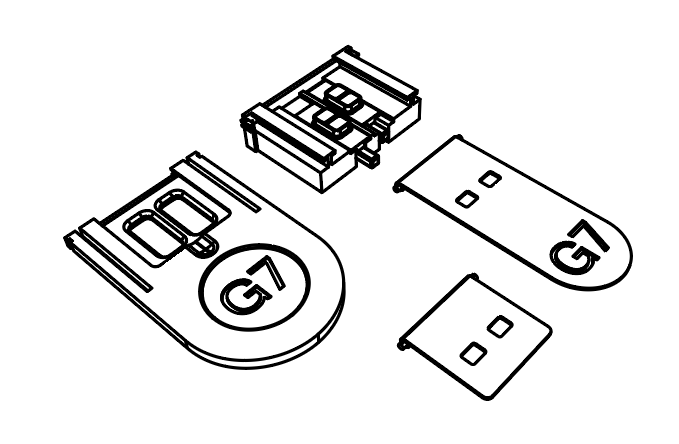

MECHANICAL COMPARTMENT LATCH

CAD to Part Time 25 hrs

Part Cost $14

Size 14cm x 9cm x 2cm

Printed on METHOD

Model Material MakerBot Tough

Support Material MakerBot PVA

Engineers design their parts in CAD using CATIA then get instant feedback using 3D printing.

A SUPPLIER HALF A WORLD AWAY

Working as a supplier for some of the largest aircraft manufacturers has unique challenges. Tight deadlines and, most notably, the expectations for innovation have never been higher. As a subsidiary, Jamco America had access to industrial 3D printers, but the printers were located in the Tokyo headquarters and the parts came with up to a one month lead time. Local service providers took several weeks at minimum and costs of several hundreds of dollars per part.

In an attempt to reduce time, Jamco America spent a couple thousand dollars on an entry-level 3D printer. But the printer “did not have the balance between performance and cost,” says John Cornell, Manager of Product Research & Development. “It was always breaking down and producing parts that didn’t have the quality that met our requirements.”

A render of a first class cabin designed and manufactured by Jamco for a global airline.

BRINGING 3D PRINTING ON-SITE

John and his agile team of eight engineers set out to buy an industrial 3D printer. “I was originally pushed to look at a high budget printer, but I convinced management to look at a lower price point which would allow us to potentially have multiple printers printing in parallel.” After comparing 15 printers, they landed on the MakerBot METHOD. “[METHOD] helped us improve our process to meet our goals of rapid prototyping and many iterations, very quickly.” The combination of a Circulating Heated Build Chamber and PVA water-soluble support material also enable industrial-level dimensional accuracy while printing highly complex geometries.

| Outsourced 3D Printing | METHOD in-house | |

|---|---|---|

| Total Cost | $350 ▲ | $14 ▼ |

| Total Time | 30 days ▲ | 1 day ▼ |

PRINTING COMPLEX AIRCRAFT LATCHES

After a simple plug-n-play setup, Jamco began 3D printing functional prototypes immediately and has produced a wide variety of functional prototypes. The team has recently been engaged with producing a dual latch system for an aircraft privacy door, taking advantage of MakerBot’s soluble support materials. ”Complex parts such as latches, with the necessary overhangs, require some sacrificial material.” The company is also testing the ergonomics of an aircraft crew step, with rapid prototyping allowing testing and iterating while demonstrating the functional and spatial usability or ergonomics for the part. They have been able to print 48 inch-long extrusions, printed in multiple sections and bonded together, costing much less than outsourcing alternatives.

Design Engineers at Jamco America utilize METHOD to quickly 3D print complex assemblies with tight tolerances before moving on to the next step in production.

Jamco America use the MakerBot METHOD 3D Printer to bring complex aircraft parts to market faster.

Originally published for makerbot.com